Pictures shown are for illustrative purpose only. Actual product may vary

Pictures shown are for illustrative purpose only. Actual product may vary - Show results for

- Share

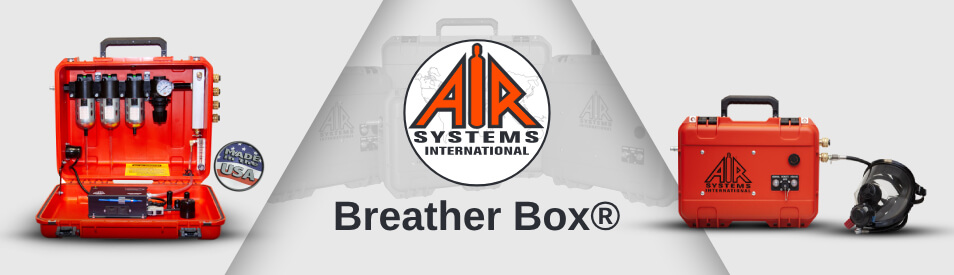

AIR Systems Breather Box - A Portable Grade-D Breathing Air Filtration System

Resource Description

Table Of Contents

- Introduction

- About Grade-D Breathing Air Systems

- How Does the Breather Box Work?

- How to Use the Breather Box?

- Conclusion

Introduction

Air Systems International, Inc. is a leader when it comes to Grade-D breathing air filtration and confined space ventilation.

Air Systems offers a wide range of safety equipment for Construction, Industrial, Military Defense, Government, Fire / Rescue, and other applications.

In this article, you will learn about the Breather Box and find out how to use it.

About Grade-D Breathing Air Systems

A Grade-D breathing air filtration system is used to provide Grade-D breathing air for workers.

Grade-D Air Quality Must Meet/Exceed the Requirements Below:

- Oxygen: 19.5%-23.5% (20%-22% Canada)

- Hydrocarbon (condensed oil): 5 mg/m3 max (<1Mg/m3 in Canada)

- Carbon Monoxide (CO): 10 ppm max (5 ppm in Canada)

- Carbon Dioxide (CO2): 1000 ppm max (500 ppm in Canada)

- Odor: No noticeable tastes/smells

- Water Content:

- High-pressure cylinder air must have a dew point of at least -50° F at 1 atmosphere (14.7 psi)

- Low-pressure breathing air must have a dew point of at least 10° F below the ambient temperature at 1 atmosphere (14.7 psi)

- Canada: 5° C below lowest temperature, 27 ppm max water vapor

- Total Volatile Hydrocarbons (Canada): 5 ppm max

A typical Grade-D breathing air system consists of a compressor, Grade-D filtration, air distribution (POA), and respirator.

The size & complexity of the breathing air system can vary based on the number of workers it will serve and whether it needs to be portable or fixed. Note that the core components mentioned above must always be included.

To size the breathing air system, the first step is to determine the type and number of airline respirators required. It’s important to review the different types of airline respirators, along with their specific flow & pressure requirements. According to NIOSH, airline respirators are classified as Type-C or Type-CE. While Type-CE respirators are specifically designed for abrasive blasting, they still require the same airflow as Type-C respirators. There are many different air boxes available.

How Does the Breather Box Work?

The Breather Box is a portable Grade-D filtration system that provides breathing air for a specific number of workers. It filters incoming air from a compressor to ensure that the respirator users receive Grade-D quality air. In addition, it monitors for carbon monoxide and/or oxygen levels.

This AIR Systems air filtration system features three stages of filtration:

- The 1st stage element is designed to filter bulk water & particulate, it has an auto drain function.

- The 2nd stage coalescing filter eliminates atomized oils, mists as well as ultra-fine particulates, and it is also equipped with an auto drain.

- The 3rd stage filter removes organic vapors & odors, it has a manual drain.

The standard CO airline monitor works on disposable 9V batteries, 8-16V DC, or 115 VAC, ensuring continuous air monitoring. The workers are alerted to high carbon monoxide content via a useful external audible alarm & light.

Some models come with a remote alarm jack. Point-of-Attachment boxes allow the extension of the respirator's use beyond 300 ft.

How to Use the Breather Box?

Use the Air Systems International Breather Box in the upright position. Follow the steps below.

- Secure a primary air source. Make sure that the air source provides sufficient airflow and discharge pressure. The required flow rate & pressure depend on the number & type of respirators

- Check the airline monitor:

- Ensure the monitor has fresh 9V batteries, and turn the unit on.

- Connect the remote signal cable, 115 VAC plug as well as air sample hose to the airline monitor.

- Set the “ON/OFF/TEST” switch to the “ON” position and then wait approximately 30 seconds so that the readout stabilizes. If the display shows anything other than "00", calibration may be necessary. The remote signal cable is not applicable to the BB15 series.

- Plug the extension cord into a 115 VAC outlet. If AC power is unavailable, the CO monitor can run on 9V batteries.

- Connect the remote alarm assembly (optional, DC only) to the remote alarm jack. Not applicable to the BB15 series.

- Close the flowmeter. Turn the control knob fully clockwise. Avoid over-tightening.

- Connect the air source (150 psi max.) to the inlet fitting.

- Hold the "ON/OFF/TEST" switch in the “TEST” position to activate local & remote audible/visual indicators. If the indicators do not activate, check all electrical connections and contact the factory repair department. The alarm function can be tested at any time by lifting the “ON/OFF/TEST” switch to the “TEST” position.

- Connect the desired respirators & hoses to the quick-connect couplings. Note that some models do not have respirator connections.

- Adjust the outlet pressure according to the respirator manufacturer’s recommendations. To increase pressure, turn the knob clockwise, to decrease pressure, turn it counterclockwise.

- Adjust the CO monitor air sample flow rate. Just turn the flowmeter control knob counterclockwise until the ball hovers between 50 &100 cc/min. At this point, the system is ready for operation. The air sample will be analyzed and the CO concentration will be displayed in ppm. The green "NORMAL" operation light will illuminate. The red "HIGH CO" light will flicker faintly about once per second when CO levels are below 10 ppm (5 ppm Canadian). If the CO concentration level exceeds the alarm set point, then the green "NORMAL" light will turn off, the red "HIGH CO" light will stay on, the audible alarm will activate, and the remote alarm connections will energize. When the CO level drops below the alarm set point, alarm indicators will deactivate and resume normal operation.

Conclusion

The Breather Box® is an effective solution. It is the industry standard in Grade-D air filtration. This system is easy to use. Just follow the instructions above.

On Prime Buy, there is a broad range of AIR Systems products: AIR Systems HVAC products, AIR Systems ventilation solutions (including AIR Systems International blowers & fans, ventilation ducting), hoses, CO monitors (including the CO 91-14LAC CO monitor), POA products, Multi Air Command Kits, regulators, alarms, AIR Systems filters (including AIR Systems compressor filters), fittings (including plugs & sockets), note that it is important to choose the right air compressor fitting size or fitting size for other products, and more.

Air Systems Inc. offers reliable solutions, find what you need on our website!

Pictures shown are for illustrative purpose only. Actual product may vary

Pictures shown are for illustrative purpose only. Actual product may vary